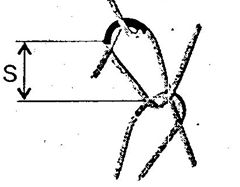

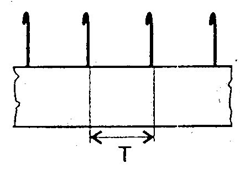

Çözgülü örmede desen raporunu anlatmadan aşağıdaki temel bilgileri öğrenmekte fayda vardır.

- Örgü raporları gösterilirken en soldan sağa doğru sıfırdan başlayarak numaralandırma yapılır. Raporun ilk gösterildiği nokta hangisi ise o sıfır olarak değerlendirilir. Örneğin aşağıdaki gösterimde en altta 4 adet nokta var. Eğer en soldakine sıfır demiş olsaydık raporu; 1-2/2-1 olarak adlandırırdık ve bu teknik gösterimde yanlıştır. Bu nedenle soldan ikinci noktaya sıfır, soldan üçüncü noktaya ise 1 diyerek devam edeceğiz, çünkü hareketler bu soldan ikinci nokta üzerinden başlamış. Böylece örgü raporumuz 1-0/0-1 olarak isimlendirilir.

- Raporda ipliğin iğne(nokta) üzerinden geçtiği yön kodlamada kullanılır, bu bilgi bize özellikle açık/kapalı örgüleri kodlamada işe yaramaktadır.

- Tekrar raporu gösterilirken, her iğnenin kodu yazılarak sıradaki iğneye geçerken - işareti konulur, raporun bittiğini göstermek içinse = işareti konulur.

- Açık Örgü: İlmeğin iğne etrafında tam dolanmadan diğer iğneye geçiş yapmasıyla oluşur, daha gevşek görünümdedir.

- Kapalı Örgü: İlmeğin iğneye tam tur yaptıktan sonra diğer iğneye geçişiyle oluşur, daha sıkı görünümdedir.

Çözgülü örmede kullanılan 6 adet temel örgü çeşidi vardır, bunlar;

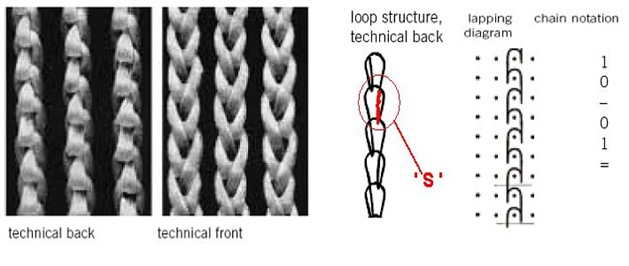

1. Franze (Piller Stitch) Örgü:

Bu örgüde iplik aynı iğne etrafında hareket yapar ve yanal bağlantılar olmadığından bir tekstil yüzeyi oluşturulmaz.Bunun sonucu olarak, franze örgü tipi çözgülü örmede genellikle gramaj vermekte, boylamsal yönde stabil yapı sağlamakta ve dolgu amaçlı kullanılır. İki tip franze örgü vardır.

1.a. Açık Franze:

Örgü raporu 1-0/01 dir, yani 1. iğnede 1'den 0' a, 2. iğnede 0' dan 1' e doğru bağlantı yaparak tekrar eder.

Boydaki Tekrar: 2 tur

Tekrardaki iplik ? : 5.5

Örgüdeki ayak yönü: Her turda değişir (sağ-sol)

1.b. Kapalı Franze:

Örgü raporu 1-0 dır, yani birden sıfıra doğru tekrarlayarak ilerler.

closed pillar stitch:

Boydaki Tekrar: 1 tur

Tekrardaki iplik ? : 2,75

Örgüdeki ayak yönü: Aynı yönde uzanır (sağdan sola)

2. Trikot (1x1 lap) Örgü:

When working a 1 x 1 stitch also called tricot stitch, the thread is laid alternatively over two adjacent needles. During under-lapping the lateral connection between the wales and so a textile construction is produced.

Because the under-laps change their direction in every course, the heads of the loops lay also alternatively from the left to the right in every course. This inclination of the loop heads is a characteristic of warp-knitted fabrics.

The closed 1 x 1 stitch is very light and elastic. However, it is often used in connection with other bindings or binding elements (locknit, velvet, ...). The open 1 x 1 stitch is also very light but is less stable in shape.

2.1. Açık Trikot:

open pillar stitch:

repeat in length = 2 courses

yarn parts per repeat = 6

2.2. Kapalı Trikot:

open pillar stitch:

repeat in length = 2 courses

yarn parts per repeat = 6

2.2. Kapalı Trikot:

closed 1 x 1 stitch:

repeat in length = 2 courses

yarn parts per repeat = 6

closed 1 x 1 stitch:

repeat in length = 2 courses

yarn parts per repeat = 6

3. Tuch (2x1 lap) Örgü:

The 2 x 1 stitch differs technically from the 1 x 1 stitch by the under-lapping which is extended about one needle space. The longer under-laps highly influence the fabric properties. The fabric gets less elasticity (gets less stretch) in width and is more dense than the 1 x 1 stitch.

The 2 x 1 stitch can be worked open or closed.

With the same no. of needles, the fabric with the open 2 x 1 stitch is wider than that of the closed 2 x 1 stitch.The yarn consumption is a about 1/4 higher than that of the 1 x 1 stitch.

closed 2 x 1 stitch

repeat in length = 2 courses

yarn parts per repeat = 8

open 2 x 1 stitch:

repeat in length = 2 courses

yarn parts per repeat = 8

Closed 2 x 1 stitch and closed 1 x 1 stitch,counter lap (lock knit).

In greatest demand for the underwear Industry is locknit,produce in various qualities and yarns,such as chemical fibers and natural Polymers(viscose,cuprammonium or acetate) or chemical fibers with synthetic Polymer (Polyamide,Polyester etc).The run-in ratio for this article generally 3 : 4.

3.1. Açık Tuch:

3.2. Kapalı Tuch:

4. Satin (3x1 lap) Örgü:

If the under-lap is increased by one needle space, the 2 x 1 stitch becomes a 3 x 1 stitch which, in conjunction with other stitch constructions - as pillar or 1 x 1 stitch – will produce velvet or fabrics with less longitudinal and lateral stretch. The longer under laps cross two wales on the technical back of the fabric and, after raising and shearing treatment, this fabric takes on a velvet appearance.

closed 3 x 1 stitch:

repeat in length = 2 courses

yarn parts per repeat = 10

open 3 x 1 stitch:

repeat in length = 2 courses

yarn parts per repeat = 10

4.1. Açık Satin:

4.2. Kapalı Satin:

5. Samt (4x1 lap) Örgü:

If the underlap of the 3 x 1 stitch is extended by 1 or more needle spaces the 4 x 1 stitch is produced. The 4 x 1 stitch therefore has the longest underlap of all the common regular stitch constructions. Because of the long underlap the 4 x 1 stitch has a very high stability in longitudinal direction.

The yarn consumption is twice as much as of the 1 x 1 stitch.

closed 4 x 1 stitch

repeat in length = 2 courses

yarn parts per repeat = 12 or more

open 4 x 1 stitch:

repeat in length = 2 courses

yarn parts per repeat = 12 or more

5.1. Açık Samt:

5.2. Kapalı Samt:

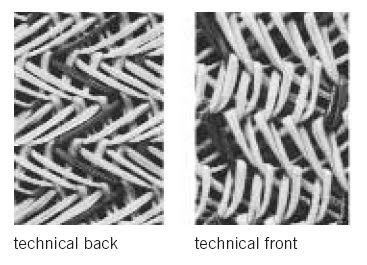

6. Atlas Örgü:

he specialty of the atlas constructions is that the laps are continued over two or more courses in one direction and after a turning course the laps return in opposite direction to the starting point.

The characteristic of the atlas construction is the inclination of the loop heads which changes from turning course to turning course. The stripes formed in this way depend in width on the number of stitches between the turning points and the adjusted number of courses (cpi).

The Atlas is said to be open if the loops between the turning points are open. In case of a closed atlas construction, the loops between the turning points are closed.

The turning courses can be open or closed.

The number of courses from turning course to turning course is most important for the fabric appearance and has to be indicated in the binding description.

The repeat of a 4-row Atlas construction includes 8 courses whereby the stitches of 4 rows at a time incline alternately to the left and to the right. Half of the repeat of the Atlas construction is also called the mirror.The open Atlas belongs to the lightest warp knitted fabrics and is more often worked than the closed Atlas construction.

4-row Atlas, closed, turning points open:

repeat in length = 8 courses

yarn parts per repeat = 24

4-row Atlas, open, turning points closed:

repeat in length = 8 courses

yarn parts per repeat = 24

3-row back-lapped Atlas, closed, turning points closed:

If the lapping of the Atlas is changed to displace during the underlap motion by one needle gap more, similar to the 2 x 1 stitch, the Atlas is called a back-lapped Atlas construction.

Owing to the elongated underlap this back-lapped Atlas is about 1/3 heavier than the normal one.

repeat in length = 6 courses

yarn parts per repeat = 24

3-row back-lapped Atlas, open, tuning points closed:

repeat in length = 6 courses

yarn parts per repeat = 24

6.1. Açık Atlas:

6.2. Kapalı Atlas:

7. Köper Bağı:

Köper

All basic stitch constructions – pillar stitch, 1 x 1 stitch, 2 x 1 stitch, 3 x 1 stitch, 4 x 1 stitch and Atlas constructions can be worked so that the thread is laid over 2 needles in the overlapping motion. This produces two stitches next to each other whose foot connections are comparable to those of weft knitted fabrics.

The most well-known constructions of this kind are open and closed two-needle overlap pillar and – 1 x 1 stitches.

The production of these two-needle overlap constructions is only possible on warp knitting machines with well adjusted knitting elements. Moreover, these constructions can only be completed under low thread tension because a thread reserve which is formed via the sinkers is needed.

When knocking over, the foot connection of the loops lays over the sinkers on tricot machines or over the knock-over plate on Raschel machines. The friction thus created increases the tension and so yarn breakages or even needle damages may occur.

To avoid this, the yarn material should have appropriate elastic properties.

Out of above mentioned reasons, two-needle overlap constructions are not as popular as other stitch constructions.They are used e.g. when heavy fabrics should be produced with one guide bar. However, the yarn consumption is twice that of a normal pillar stitch. With normal threading two loops are formed on one needle.

Two-needle overlap pillar stitch, closed

repeat in length = 1 course

yarn parts per repeat = 5.5

Two-needle overlap pillar stitch, open

repeat in length = 1 course

yarn parts per repeat = 10.5

1 x 2 stitch

The 1 x 2 or two-needle overlap tricot stitch can be worked fully threaded or threaded one in / one out // (two-needle overlap semi-tricot). This two-needle overlap semi-tricot shows alternatively one wale with straight stitches and one wale with slanting stitches.

The fully threaded two-needle overlap construction contains course-wise alternating slightly inclined stitches.It is often difficult to distinguish between the closed and the open two-needle overlap semi-tricot in the fabric. In the lapping diagram the differences in construction can clearly be recognized but in the real fabric structure (photo) it cannot be easily distinguished whether the stitches of the changing slopes of the wales are open or closed (because of the twist). Besides, both sinker loops (foot connections in the same course, and foot connections of two courses) have the same appearance.

In spite of these difficulties, the fabrics can be distinguished in such a way that the technical back of the fabric is analyzed by the position of the sinker loops and then a left or right sloping stitch has to be turned so that the stitch lying above shows the back loop according to the definition "stitch”. Afterwards the twisted stitch is examined and it can be seen if there is an open or closed stitch. The closed two-needle overlap tricot stitch has closed stitches in the sloped wales.

A further distinguishing feature is the straight wale. The stitches of the semi-closed two-needle overlap tricot stitch are distorted, whereas the same stitches in the semi-open two-needle overlap tricot are straight and rather uniformly formed.

1 x 2 stitch, closed

repeat in length = 2 courses

yarn parts per repeat = 11

1 x 2 stitch, open

repeat in length = 2 courses

yarn parts per repeat = 11